Product Catalog

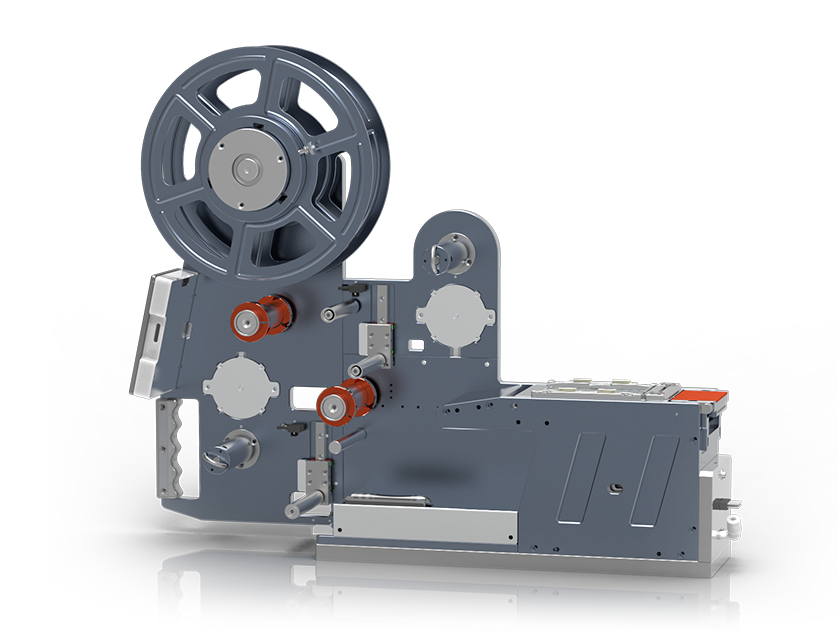

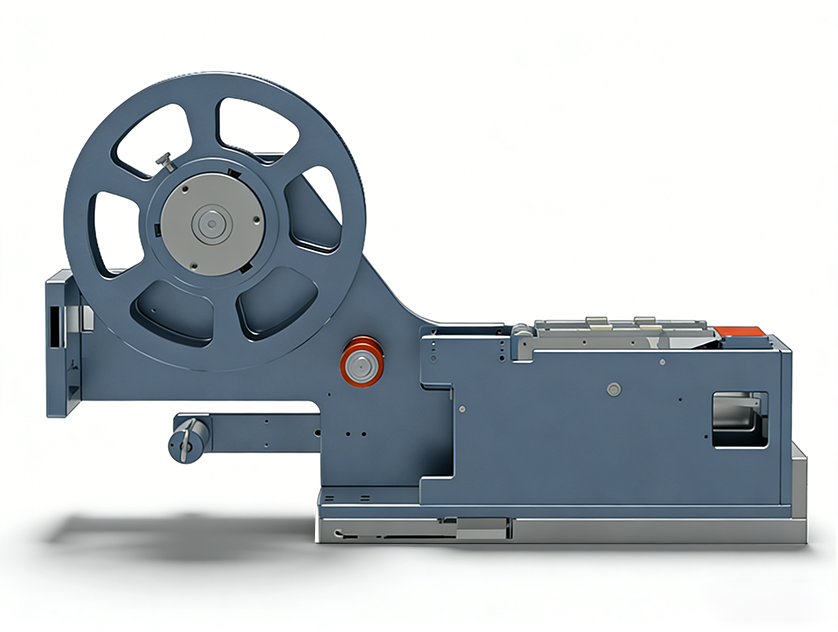

RED-CMF-S

Short Feeder

More aesthetically pleasing layout inside the equipment

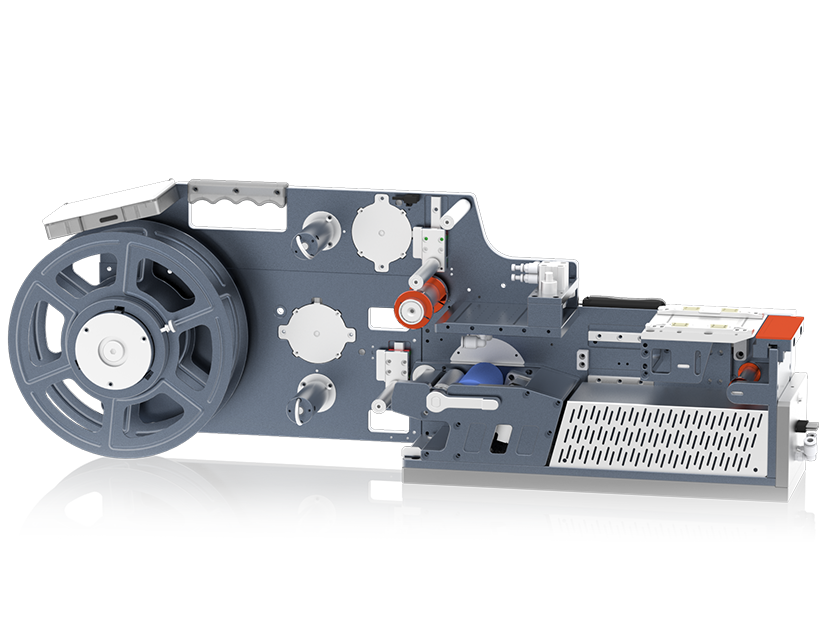

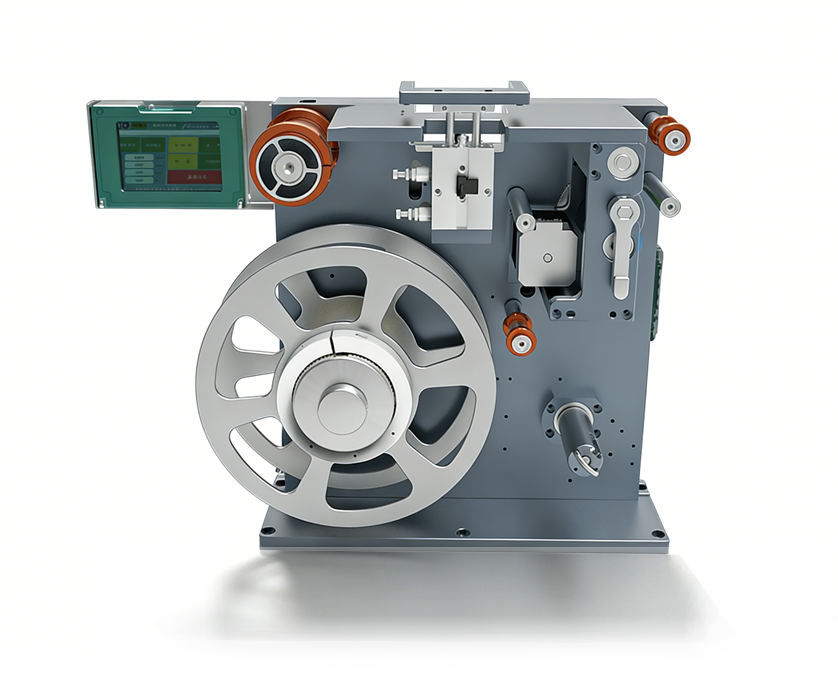

RED-CMF-L

Long Feeder

More convenient for material change outside the equipment

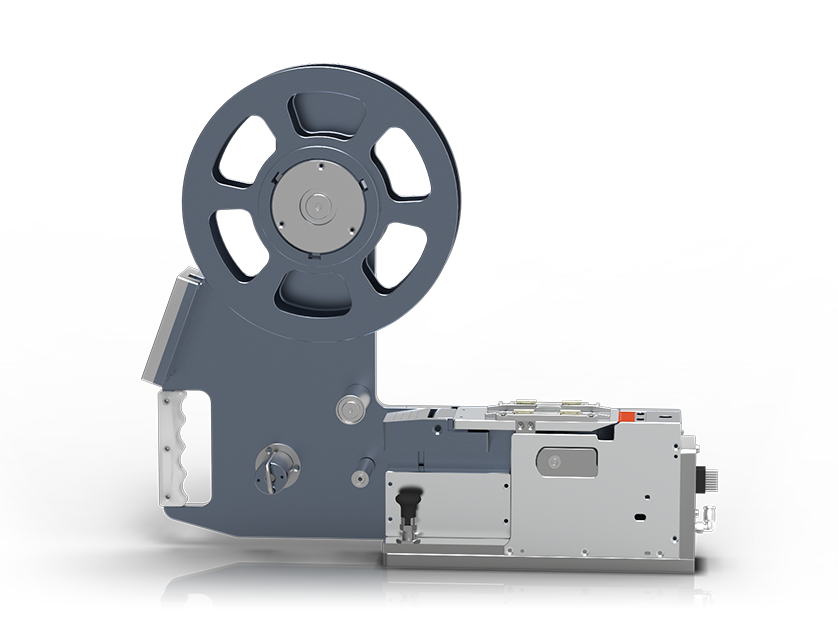

ARD-CPF-S

Compact Short Feeder

More layout in limited space

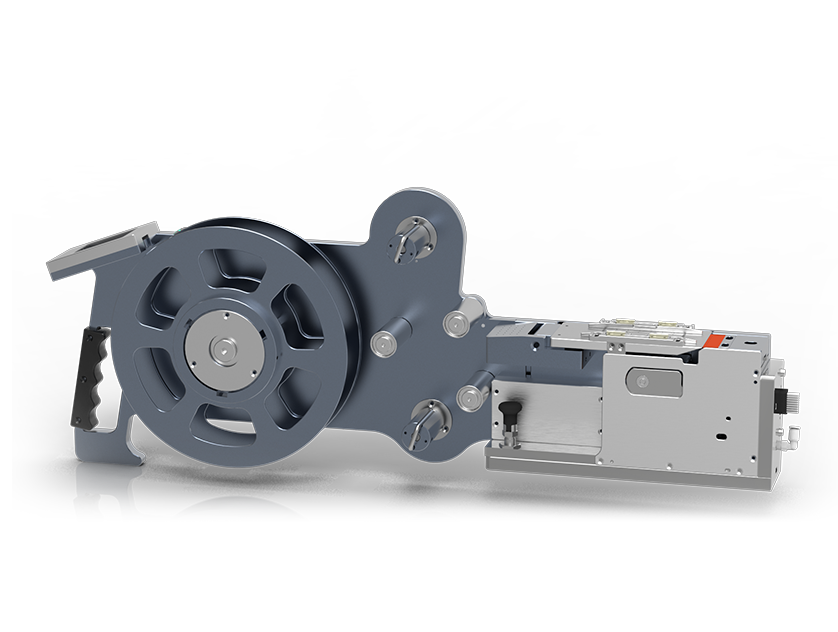

ARD-CPF-L

Compact Long Feeder

More layout in limited space

LBP-S

Various Roll Materials

One model can achieve peeling

RED-CMF

Easy Tear Feeder

For easy-to-peel label materials

Application Scenarios

Feeding Principle

Advantages

The peel-first-then-pick mode can peel multiple rows of materials at a time with fast action and high efficiency, simple structure, and convenient operation. Obvious relative cost advantage.

Disadvantages

Materials are pushed to the non-stick platform by release force, while subject to reverse friction interference, some materials are prone to feeding position deviation.

Selection Parameters

1. Backing paper width

2. Coil inner/outer diameter

3. With/without upper protective film

4. Size and arrangement of single material

Basic Requirements

• Material and backing film reverse folding test easy to separate, no obvious overflow of glue.

• Backing paper priority PET material and no elasticity, thickness 0.05mm is best;

• No knife marks on backing paper, otherwise abnormal breakage or delamination will occur during peeling;

• No joints on backing paper, reserve 50cm blank tape at head and tail, material distance from edge not less than 5mm, single material front, back, left and right need to have a gap greater than 2mm.